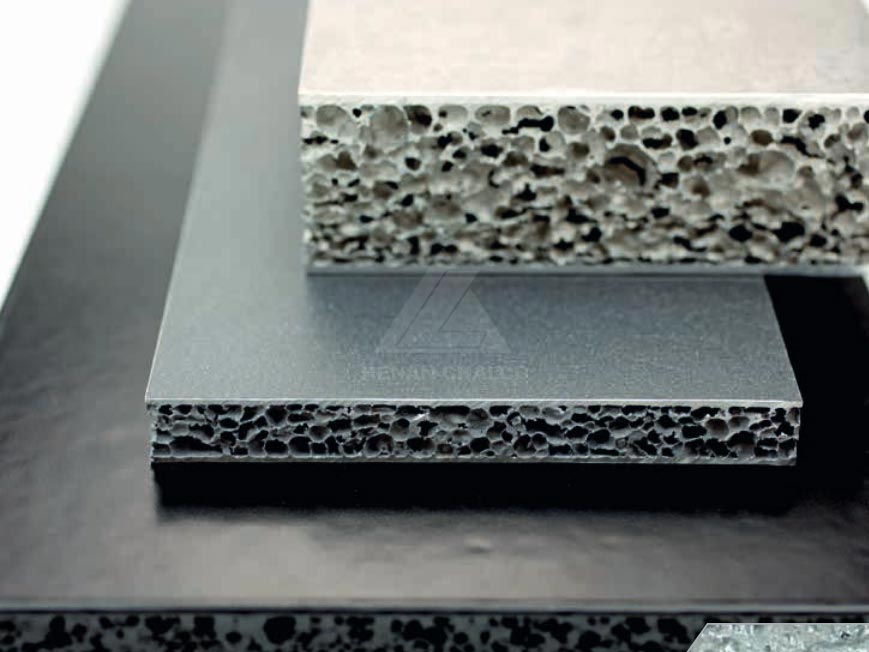

Aluminum foam sandwich is the three layers original material consists of a formed aluminum core sandwiched between two aluminum cover layers, the cover layers are metallic, fused to the core layer without the need for adhesives.

Specifications:

Features of Aluminum foam sandwich:

Deep processing of Aluminum foam sandwich:

Application of aluminum foam sandwich:

Specifications:

| Sheet size | 1000mm×2000mm |

| Thickness | 9--80mm |

| Cover layer thickness | 0.75--10mm |

| Flatness of sheets | 1mm/1000m |

| Thickness tolerance | +/-0.5mm |

| Surface weight(sample plate 25mm/1.2mm) | 10.5kg/m2 |

| E-module foam | 5 GPa |

| E-module 1/10/1 | 21 GPa |

| E-module 2/28/2 | 18 GPa |

| Tensile strength | 120--200MPa |

| Compressive strength of foam | 4--8MPa |

| Thermal expansion | 25×10-6 1/K |

| Thermal Conductivity | 10--15W/mK |

| Cover layer alloy | 6082/5754 |

Features of Aluminum foam sandwich:

| 1. Max. 60% weight savings | Aluminum foam panel has lower density than paper due to its pores and cavities. |

| 2. Flexural and torsional rigidity | The three layers sandwich system provides significantly higher flexural strength than solid sheets of the same weight. |

| 3. Absorption of kinetic energy | Aluminum foam panels delivers an improved solution for vibration and safety due to its acoustic and thermal insulating properties. |

| 4. Wide-ranging processing possibilities | Conventional processes for sheet metal processing can be used when processing aluminum foam sandwich because due to the metallic bond |

| 5. Fire resistance | Aluminum foam sandwich sheets meet stringent fire safety requirements due to the non-adhesive bond of the 3 layers materials |

| 6. 100% recyclable | The foam composite can be fed back into existing materials cycles at the end of its life cycle without any problems. |

Deep processing of Aluminum foam sandwich:

| Deep drawing, punching or pressing | For 3D structure before foaming |

| Forming | The original sheets can be formed before foaming and then foamed in a forming tool. |

| Sawing, milling, laser and water jet cutting | Aluminum foam sandwich is an ideally suited for mechanical processing.Milling, sawing, drilling and modern joining techniques are not a problem. |

| Welding | Generally only the cover layers are welded while the core remains untouched and serves as a kind of welding fixture. As a result, deformation of the components is considerably reduced. |

| Screwing, reveting and bonding | The material can be easily bonded like conventional aluminum because of its metallic character, thus making it much more cost-effective. |

Application of aluminum foam sandwich:

| Transport | Transport, shipbuilding, aerospace industry etc. |

| Engineering | Machine tools etc. |

| Building services engineering | General |

| Safety engineering | Armour plating etc. |

| Energy | Consumer products, sports, equipments etc. |

| Fire protection | Safety, security doors etc. |

| Architecture | Design etc. |

| Consumer goods | Consumer products, sports equipments. |