Aluminum foam sandwich composite panels

Because aluminum foam has high energy absorption, damping and sound insulation, it can be combined with different materials, which can be used for making composite armor of anti riot car, anti tank mine composite bottom plate, ship explosion proof deck, airdrop packing box, bullet proof safety box, aluminum foam floor for train, noise insulation cabinet, sound insulation wall in building, passenger compartment of passenger ship, partition wall, sound proof burglar resisting door, and group. All rooms, aluminum foam aluminum curtain wall, marble / foam aluminum composite board, wood / foam aluminum composite sound insulation floor.

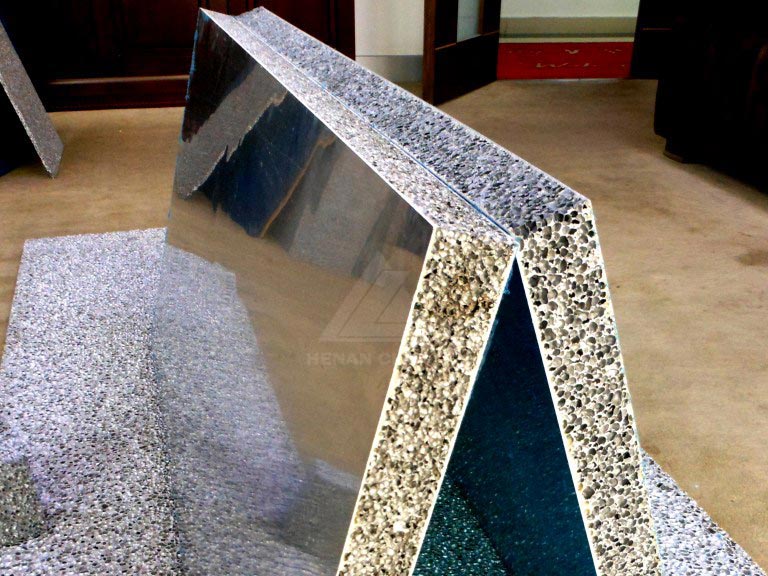

The foam aluminum is in the middle layer, and different materials are selected for the upper and lower requirements, and the bonding and welding methods are adopted. It has light weight, high specific strength, high specific stiffness, aging resistance, good energy absorption and impact resistance. Foam aluminum can be made on the basis of demand and materials such as metal (aluminum plate, steel plate, etc.), non-metal (wood, marble, glass fiber, basalt fiber, aramid fiber, carbon fiber, rubber, PE, etc.) for one-sided / double-sided clad. Aluminum foam is used as a base material. It can be made on one side or both sides. The interlayer is bonded at high temperature and hot pressed or combined at room temperature. It has light weight, high specific stiffness, aging resistance, good energy absorption and impact resistance. By adjusting the material and size of foam aluminum and panel, it can meet different performance requirements of car structure, floor, box, building, furniture and other fields.

Advantages:

1. the aluminum foam sandwich composite panels have high stiffness (flexural strength), which is similar to the flexural strength of granite. Compared with the traditional wooden floor and honeycomb aluminum floor, the aluminum foam sandwich composite plate has the advantages of high strength, weight reduction, shock isolation, no combustion and no collapse.

2. Armor plate / foam aluminum / common stiffness is more than 7 times the solid armor plate of the same mass per unit area, which is very beneficial to improving the strength of military equipment. The light armour developed by the United States is mainly composed of three layers of alumina ceramic panel, foam aluminum and resin matrix composite. The thickness of the interlayer is alumina ceramic plate 17.8mm, foam aluminum 19mm, resin matrix composite 14mm, and the total thickness is about 51mm.

3. Anti armored vehicle composite armor: 2mm manganese steel plate (or alloy plate) /15 ~ 20mm thick foam aluminum plate /1mm thick steel plate (inner layer), the weight can be reduced by more than 1/3.

4. At present, the internal damping material of military airdrop packaging box is high-density plastic foam. The energy absorbing capacity of high-density plastic foam is only about 1/10 of the aluminum foam material, which is much lower than that of the foam aluminum material. The use of aluminum foam can reduce the vibration by an order of magnitude. The aluminum foam packing box has the outstanding quality and excellent performance that other similar products can not match. It can be applied to the packaging boxes of weapons and equipment such as missile launcher, ammunition packaging boxes such as missiles, field medical boxes, field command operating boxes, field equipment packaging boxes, field military supplies packaging boxes, etc., and become air drop safety packaging boxes of equipment, ammunition, material transportation under combat environment.

5. The performance of explosion proof deck made of homogeneous steel plate (or Ti-6Al-4V alloy) 5 to 10mm/ foam aluminum will be much higher than that of high density plastic foam composite explosion-proof deck. The combination of foam aluminum plate and homogeneous steel plate can be bonded by high temperature curing resin adhesive, preferably metallurgical bonding.

6. Marble composite aluminum foam panel is the existing heavy natural stone special cutting, processing about 2mm thickness and joint aluminum foam products. The product not only maintains the original strength of the board, but also realizes the lightweight of the stone. It can be widely used in building interior and exterior decoration, conveyor equipment (railway vehicles), elevator interior materials, ordinary furniture and kitchen furniture, renovation of old buildings, ceramic tile substitutes and so on.

Because aluminum foam has high energy absorption, damping and sound insulation, it can be combined with different materials, which can be used for making composite armor of anti riot car, anti tank mine composite bottom plate, ship explosion proof deck, airdrop packing box, bullet proof safety box, aluminum foam floor for train, noise insulation cabinet, sound insulation wall in building, passenger compartment of passenger ship, partition wall, sound proof burglar resisting door, and group. All rooms, aluminum foam aluminum curtain wall, marble / foam aluminum composite board, wood / foam aluminum composite sound insulation floor.

The foam aluminum is in the middle layer, and different materials are selected for the upper and lower requirements, and the bonding and welding methods are adopted. It has light weight, high specific strength, high specific stiffness, aging resistance, good energy absorption and impact resistance. Foam aluminum can be made on the basis of demand and materials such as metal (aluminum plate, steel plate, etc.), non-metal (wood, marble, glass fiber, basalt fiber, aramid fiber, carbon fiber, rubber, PE, etc.) for one-sided / double-sided clad. Aluminum foam is used as a base material. It can be made on one side or both sides. The interlayer is bonded at high temperature and hot pressed or combined at room temperature. It has light weight, high specific stiffness, aging resistance, good energy absorption and impact resistance. By adjusting the material and size of foam aluminum and panel, it can meet different performance requirements of car structure, floor, box, building, furniture and other fields.

| Density | 0.25g/cm³~0.75g/cm³ |

| Porosity | 75%~90% |

| Bore diameter | 1—10mm,mainly 4—8mm |

| Energy absorption | 8J/m3~30J/m3 |

| Compressive strength | 3Mpa~17Mpa |

| Bending strength | 3Mpa~15Mpa |

| specific strength | It can bear more than 60 times its own weight. |

| Others | Fire resistance does not burn, does not produce toxic gases; corrosion resistance, long service life. Product Specification: 2400mm*800mm*H or customized production according to customer requirements |

Advantages:

1. the aluminum foam sandwich composite panels have high stiffness (flexural strength), which is similar to the flexural strength of granite. Compared with the traditional wooden floor and honeycomb aluminum floor, the aluminum foam sandwich composite plate has the advantages of high strength, weight reduction, shock isolation, no combustion and no collapse.

2. Armor plate / foam aluminum / common stiffness is more than 7 times the solid armor plate of the same mass per unit area, which is very beneficial to improving the strength of military equipment. The light armour developed by the United States is mainly composed of three layers of alumina ceramic panel, foam aluminum and resin matrix composite. The thickness of the interlayer is alumina ceramic plate 17.8mm, foam aluminum 19mm, resin matrix composite 14mm, and the total thickness is about 51mm.

3. Anti armored vehicle composite armor: 2mm manganese steel plate (or alloy plate) /15 ~ 20mm thick foam aluminum plate /1mm thick steel plate (inner layer), the weight can be reduced by more than 1/3.

4. At present, the internal damping material of military airdrop packaging box is high-density plastic foam. The energy absorbing capacity of high-density plastic foam is only about 1/10 of the aluminum foam material, which is much lower than that of the foam aluminum material. The use of aluminum foam can reduce the vibration by an order of magnitude. The aluminum foam packing box has the outstanding quality and excellent performance that other similar products can not match. It can be applied to the packaging boxes of weapons and equipment such as missile launcher, ammunition packaging boxes such as missiles, field medical boxes, field command operating boxes, field equipment packaging boxes, field military supplies packaging boxes, etc., and become air drop safety packaging boxes of equipment, ammunition, material transportation under combat environment.

5. The performance of explosion proof deck made of homogeneous steel plate (or Ti-6Al-4V alloy) 5 to 10mm/ foam aluminum will be much higher than that of high density plastic foam composite explosion-proof deck. The combination of foam aluminum plate and homogeneous steel plate can be bonded by high temperature curing resin adhesive, preferably metallurgical bonding.

6. Marble composite aluminum foam panel is the existing heavy natural stone special cutting, processing about 2mm thickness and joint aluminum foam products. The product not only maintains the original strength of the board, but also realizes the lightweight of the stone. It can be widely used in building interior and exterior decoration, conveyor equipment (railway vehicles), elevator interior materials, ordinary furniture and kitchen furniture, renovation of old buildings, ceramic tile substitutes and so on.