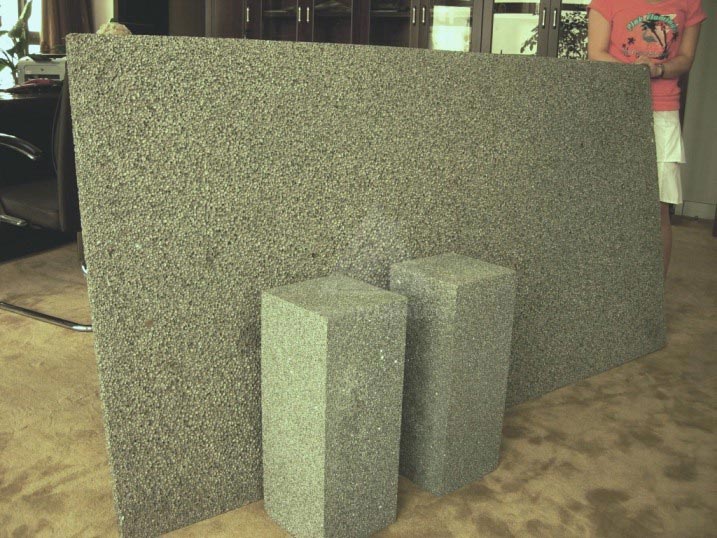

Shaped foam aluminum component

The ultra light metal structure with closed cell aluminum foam is the key point. Due to the special pore structure, the structural material is light and multifunctional, because the aluminum foam has high damping and mechanical impact energy absorption (for example, motorcycle crash helmet, automobile insurance, packaging technology). Due to the demand of civil and high-tech fields such as automobiles, the foam aluminum profile parts are becoming the frontiers in the field of foam metal preparation. The traditional melt method to prepare shaped parts can only be completed by machine addition, which is difficult and costly. At present, Germany has foamed aluminium anti-collision composite parts on high gear cars. Powder metallurgy method was used. It can meet the requirements of different uses and shapes.

Technical Indicators: Energy absorption is 6*104KJ/m3.

Advantages: compared with traditional plastic bumpers, the Shaped foam aluminum components are environmentally friendly, aging resistant, rigid and easy to spray paint.

At present, the Audi A8 car has adopted the aluminum foam bumper and the foam aluminum profile skeleton. Besides the bumper, the foamed aluminum is filled inside the profiles of the bottom beam, the front longitudinal beam, the rear longitudinal beam, the roof frame, the A column and the B column, so that it becomes the safest anti-collision car.

Foam aluminum has the characteristics of easy processing, sawing, cutting, planing, milling and so on. It is easy to be processed into various boards, bars, bars and various special-shaped parts.

Here you can find variety of Chalco Foam Aluminum shapes and sizes, available for order.

In fact, almost any of your ideas and sketches (drawings) can be performed in porous aluminum.

You don't need to pay for preproduction or tooling fee, when you order the dimensions mentioned on that page.

Only if you need larger sizes, we will make some upgrade of our equipment and we tell you about it.

The ultra light metal structure with closed cell aluminum foam is the key point. Due to the special pore structure, the structural material is light and multifunctional, because the aluminum foam has high damping and mechanical impact energy absorption (for example, motorcycle crash helmet, automobile insurance, packaging technology). Due to the demand of civil and high-tech fields such as automobiles, the foam aluminum profile parts are becoming the frontiers in the field of foam metal preparation. The traditional melt method to prepare shaped parts can only be completed by machine addition, which is difficult and costly. At present, Germany has foamed aluminium anti-collision composite parts on high gear cars. Powder metallurgy method was used. It can meet the requirements of different uses and shapes.

Technical Indicators: Energy absorption is 6*104KJ/m3.

Advantages: compared with traditional plastic bumpers, the Shaped foam aluminum components are environmentally friendly, aging resistant, rigid and easy to spray paint.

At present, the Audi A8 car has adopted the aluminum foam bumper and the foam aluminum profile skeleton. Besides the bumper, the foamed aluminum is filled inside the profiles of the bottom beam, the front longitudinal beam, the rear longitudinal beam, the roof frame, the A column and the B column, so that it becomes the safest anti-collision car.

Foam aluminum has the characteristics of easy processing, sawing, cutting, planing, milling and so on. It is easy to be processed into various boards, bars, bars and various special-shaped parts.

Here you can find variety of Chalco Foam Aluminum shapes and sizes, available for order.

In fact, almost any of your ideas and sketches (drawings) can be performed in porous aluminum.

You don't need to pay for preproduction or tooling fee, when you order the dimensions mentioned on that page.

Only if you need larger sizes, we will make some upgrade of our equipment and we tell you about it.

| Foam aluminum disk |

|

| Foam aluminum tube pipe |

|

| Foam aluminum cylinder |

|

| Complex foam aluminum shapes |

|

| Foam aluminum block |

|