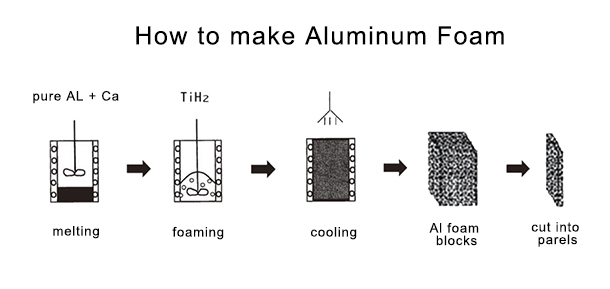

How to make aluminum foam

Production

|

2022-02-18 16:32

1. Aluminum smelting

The aluminium matrix is melted in the smelting furnace to obtain the aluminium-based

melt and then transferred to the holding furnace for static insulation. The

aluminium matrix is pure aluminium, aluminium-silicon alloy, aluminium-magnesium

alloy, aluminium-manganese alloy, aluminium-copper alloy, aluminium-zinc alloy,

aluminium-silicon-magnesium alloy, ALUMINIUM-SILICON-COPPER alloy, etc.

2. Viscosification and foaming of Aluminum melt.

Transfer the tackified

aluminium-based melt to the foaming furnace, adjust the temperature of the foaming

furnace, add the foaming agent after pre-heat treatment or surface coating

treatment, and stir continuously to make the foaming agent distribute evenly all the

time.

The foam aluminum matrix melt is poured into the thermal insulation crystallizer

through the pouring nozzle at the bottom of the foaming furnace, and then solidified

firstly under the primary cooling effect of the inner wall of the heat preservation

crystallizer.

3. Foam aluminum slab cooling

Start the cooling fan and open the atomizing spray head, to cool foam aluminum by

the air cooling and water cooling.

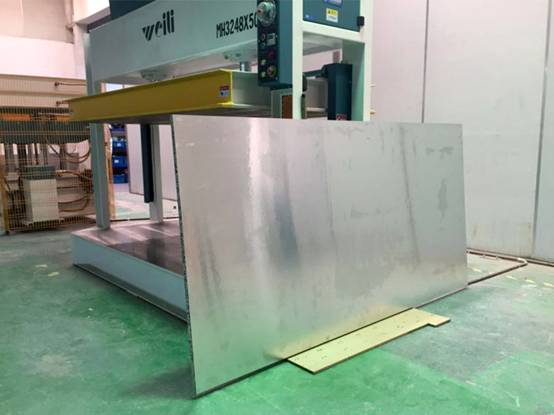

4. Foam aluminum slab ready and then saw it according to customer

requirements.

Cut out the irregular edges vertically.

Cut into the thickness required by customers to make aluminum foam.

5. Foam aluminum packing

6. Foam aluminum sheet, double-sided clad aluminum plate, or clad marble stone,

forming foam aluminum sandwich panels.