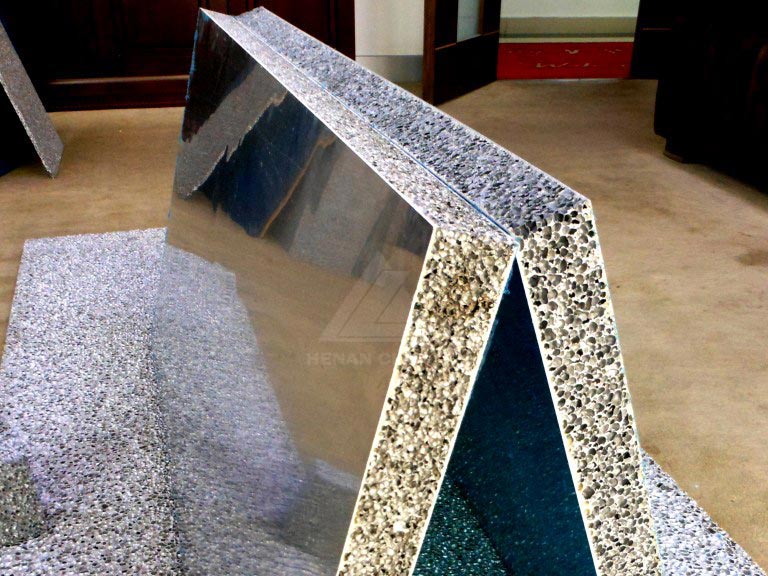

Application Field of Aluminum foam composite sheet :

1.Aluminum foam composite sheet plate has a wide range of applications. It is widely used in the rail transit industry with its properties of low density, high stiffness, sound insulation, heat insulation, fire protection, energy absorption and not releasing gas when heated.Such as in the compartment and compartment on the heat and sound insulation, energy absorption and fire, gas parts.

2. Make use of the sound insulation, sound absorption and energy absorption performance of aluminum foam for environmental protection in urban construction, such as: sound insulation screen;The automobile industry is used for energy - and sound-absorbing components, such as bumpers and mufflers.

3. Take advantage of the low density, high stiffness and low thermal conductivity of aluminum foam, widely used in energy-saving buildings, such as: thermal insulation walls and fire insulation hot, energy-saving mobile houses.

4. Suitable for military industry, sound-absorbing and antimagnetic components, such as: tank, submarine shell sandwich panel.

5. Other mechanical manufacturing, aviation and other products of heat and sound insulation, shockproof, energy absorption components can be made of aluminum foam.