c shielding, strong weather resistance, filtering ability, easy processing, easy installation, high forming accuracy, surface coating .

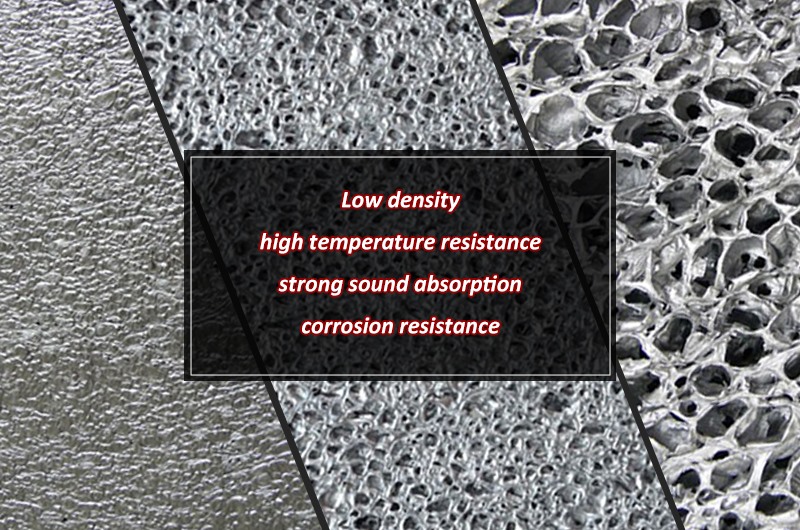

Performance characteristics of Aluminum foam for ceiling

1: Light weight: density of metal aluminum 0.1-0.4 times;

2: High specific stiffness: its bending specific stiffness is 1.5 times that of steel;

3: High damping damping performance and impact energy absorption rate: damping performance for metal aluminum 5-10 times. Aluminum foamed with 84% porosity can absorb more than 2.5MJ/M3C energy at 50% transformation.

4: Good acoustic function:Sound insulation performance (obturator) : when the acoustic frequency is between 800-4000Hz, the sound insulation coefficient of obturator aluminum foam is above 0.9.

5: Does not burn and has good heat resistance. Good corrosion resistance, weather resistance, low moisture absorption, no aging, no toxicity.

6: Easy to process: easy to cut, drill and cement; It can be bent into the desired shape by molding; Surface treatment with organic or inorganic paint; Can be skinned on both sides, forming large size lightweight, high stiffness board.