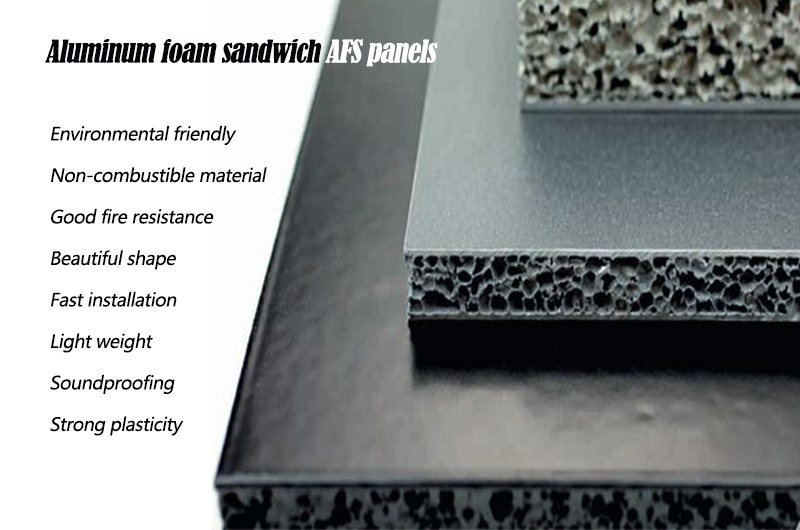

Aluminum foam sandwich AFS panels has excellent performance of aluminum foam material, and solves the disadvantage of low strength of single aluminum foam. It is a new functional material with excellent comprehensive performance and has a broad application prospect in automobile manufacturing, aviation, aerospace and other fields.

Features of Aluminum foam sandwich AFS panels:

1, light weight, per square meter weight less than 24kg, can fully reduce the cost of the structure.

2, the installation is fast, light weight, plug, installation and can be cut at will, determine the installation is simple, can improve efficiency, save time.

3,Aluminum foam sandwich AFS panels surface material and insulation materials are non-combustible or non-combustible materials, can meet the requirements of fire code.

4, fire-resistant, by special coating treatment of aluminum plate up to 10-15 years, after every ten years spraying anti-corrosion coating, the life of the plate up to 35 years.

5, Beautiful, pressing plate clear line up to dozens of colors, can cooperate with the needs of any style of building

6. Environmental protection and noise prevention, sound insulation intensity of Aluminum foam sandwich AFS panels can reach 40-50 decibels, which is a very effective sound insulation material.

7, Strong plasticity, pressure plate can be arbitrarily cut, enough to meet the needs of special design.