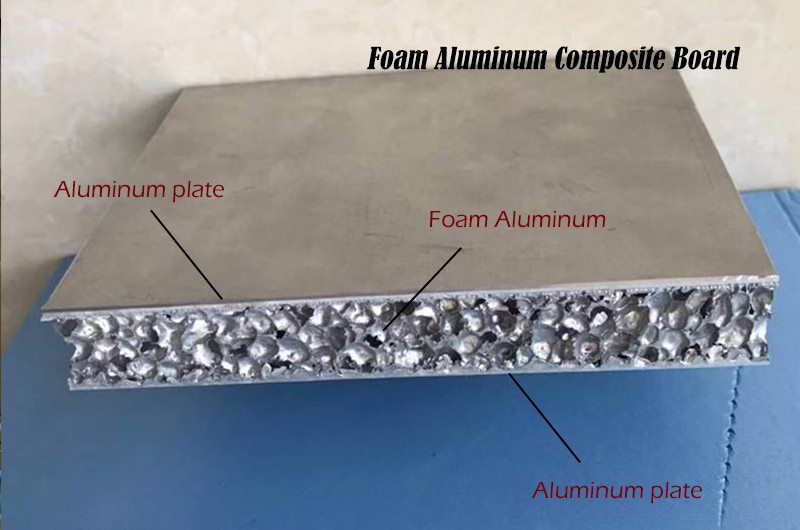

High flatness plate, two layers of aluminum plate sandwiched with all-metal foam aluminum plate structure, forming the ideal plate with extremely high flatness and extremely small deformation.

And Foam Aluminum Composite Board has the following characteristics.

1. Waterproof, flame retardant, acid and alkali resistance, moth-proof, light weight, heat preservation, sound insulation, shock absorption characteristics.

2. The same processing as wood, and the processing performance is far better than wood.

3. It is an ideal substitute for wood, aluminum and composite board.

4. The surface of the board is very smooth, high hardness, not easy to scratch, often used for making cabinets, furniture and so on.

Specifications of Foam Aluminum Composite Board :

Due to the light weight and high strength of the composite structure plate, the maximum width of the plate can be up to 1200mm while still maintaining the flatness of the board.

If matched with the longest plate length 3000mm.

Product thickness: 10-40mm

Product specifications: 1000*2000mm

Surface coating: fluorocarbon coating, polyester coating, colored oxidation.