In traditional engineering materials, holes (macro or micro) are considered as structural defects, because they are often the core of crack formation and propagation, which have an adverse impact on the physical and mechanical properties of materials. However, when the number of pores in the material increases to a certain extent, the material will produce some special functions due to the existence of holes, thus forming a new material category, that is, the so-called porous (porous) material, also known as foam material. Foamed aluminum structure sheet has a series of excellent properties: high porosity, high specific strength, high specific stiffness, energy absorption, good damping and shock absorption, corrosion resistance, high temperature resistance, electromagnetic shielding, non-toxic, easy to process, and can be applied to surface treatment of coating.

Because of its excellent physical and mechanical properties, Foamed aluminum structure sheet can be used as structural materials as well as functional materials. In general, it has the dual functions of function and structure. It is a multifunctional engineering material with excellent performance integrating function and structure. Because of its physical, thermal, acoustic and electromagnetism properties, the Foamed aluminum structure sheet itself has many physical properties, [4]. The Foamed aluminum structure sheet structure material is used to absorb energy by the super light structure and the energy absorption characteristics of the foam. At present, Foamed aluminum structure sheet is the most widely used porous metal in China. So the major manufacturers now use Foamed aluminum structure sheet as the preferred material for energy absorbing filling materials.

Properties of Foamed aluminum structure sheet :

Foamed aluminum structure sheet has ultra-low density. At present, the international advanced foam aluminum technology has been able to achieve precise control of molding density between 0.25-0.8g/cm3, which is a lightweight high-quality metal material. At the same time, it has high strength, and its bending specific stiffness can reach 1.3-1.5 times that of steel; An energy absorbing platform capable of reaching 2-10mpa in energy absorption; In terms of sound absorption performance, through the test data, the sound absorption coefficient can be more than 0.9 and the noise reduction coefficient is 0.5; The damping performance can reduce the mechanical vibration by two orders of magnitude, and the damping performance can reach 5-10 times that of metal aluminum alloy through calculation; In terms of protection performance, it can make the explosion impact decay exponentially, and its energy absorption capacity is 3-6kj / cm2.

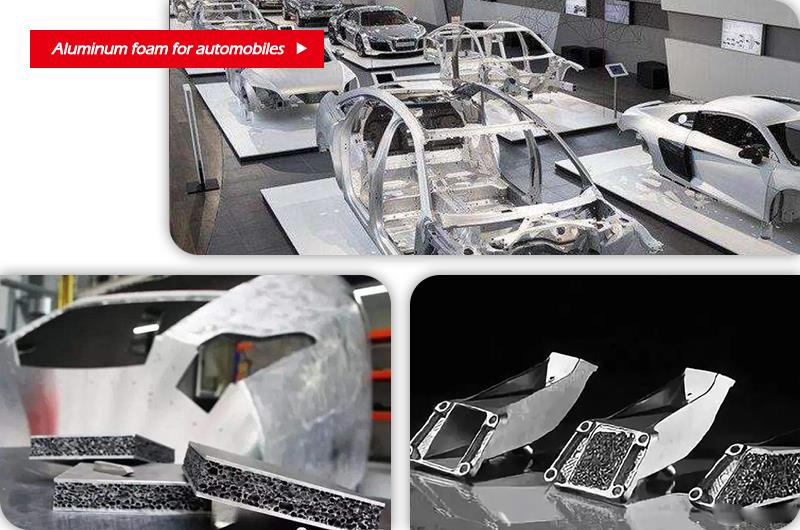

Because of its ultra-low density, high specific strength, high specific stiffness and energy absorption, Al based Foamed aluminum structure sheet can be used as an important energy absorbing structure on lightweight body. It can effectively enhance the body energy absorbing platform, and enhance the stiffness of vehicle body on the premise of ensuring lightweight index. With the maturity of the process and the improvement of the composite means, the composite Foamed aluminum structure sheet material will bring greater changes to various structural parts of the automobile.