Therefore, the preparation technology of aluminum foam has become a research hotspot in the field of new materials.The preparation process of aluminum foam is described in detail below:

1. Solid metal sintering method:

Most of the foamed aluminium produced by this method has a through-hole structure, which is due to the fact that most of the solid phase methods connect the aluminium particles to each other through sintering, and the aluminium remains solid.

1.1 powder metallurgy foaming method

The process principle is to mix aluminum powder and foaming agent powder, after compression to get a prefabricated with air-tight structure, heating the prefabricated to make foaming agent decomposition and release gas, forcing the prefabricated to expand to foam aluminum.

Powder metallurgy foaming process process:

Mixing → pressing → sintering → cooling

Characteristics: first, compared with other methods, the available alloy composition is more extensive, which is beneficial to improve the mechanical properties of aluminum foam;Second, it can directly manufacture parts with complex shapes.The disadvantages of this method are the narrow range of technological parameters, high cost and limited size of aluminum foam.

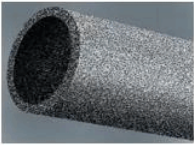

1.2 powder sintering method

This method of production consists of three processes

Powder preparation → powder compression → powder sintering

Features: advantages are simple process, low cost, disadvantages are low porosity, low material strength,

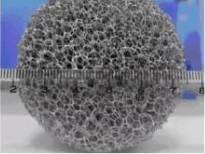

1.3. Powder forming method

It is the metal aluminum powder and foaming agent (hydrofluoric acid, aluminum hydroxide or orthophosphoric acid), additives and reaction of organic vehicle suspension, to stir it into the state of the bubble, and then put into a mould heating roasting, then plasma started to become sticky, and the effect of gas began to swell, end up with a certain strength of foam aluminum.If the slurry is directly injected into the polymer foam and the polymer material is pyrolyzed by heating, the open-hole foam material can be produced after sintering.

Powder → molding → roasting → aluminum foam

Characteristics: the aluminum foam is not strong and has cracks.